Tank Blanketing Valve | Nitrogen Blanketing Valve

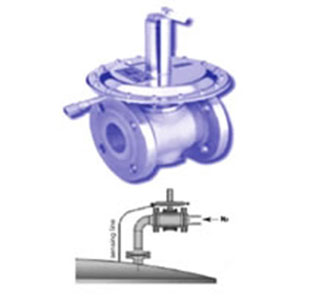

Motherwell Tank Protection 400 Series tank blanketing valve maintains a positive pressure within an enclosed storage tank by introducing a gas such as nitrogen at a required pressure.

This ‘blanket’ also prevents the stored product from vaporizing into the atmosphere, prevents contamination of the stored product and also helps to reduce product combustibility by eliminating oxygen-rich air.Tank blanketing valves offer complete protection to the storage tank product against contamination and to the storage tank itself against rupture or damage. This type of valve is mainly used in the chemical, bulk storage, and pharmaceutical industries to reduce emissions and lower the cost of product loss. In addition to preventing outside air and moisture from entering the storage vessel, a blanket gas pressure reduces the evaporation of the stored product to a negligible amount. The Motherwell 400 Series of Tank Blanketing Valve also offers primary vacuum relief for the storage tank. It does this by supplying gas to the vapor space when pressure decreases within the tank to the valves set point. Once the gas cushion is re-established, the pressure regulator closes..

Our Tank Blanketing Valve is available in a range of sizes from 15mm to 100mm.

Principle of Operation

The operating principle of the tank blanketing valve is to maintain a positive pressure within an enclosed storage tank by introducing a gas such as nitrogen at a required pressure. This ‘blanket’ also prevents the stored product from vaporising into the atmosphere, prevents contamination to the stored product, and also helps to reduce product combustability by eliminating oxygen-rich air.

The valve also offers primary vacuum relief for the storage tank. It does this by supplying gas to the vapour space when pressure decreases within the tank to the valves set point. Once the gas cushion is re-established, the pressure regulator closes.

Tank Blanketing Valve Benefits

- Range of sizes available from 15mm to 100mm

- The valve can be installed with horizontal or vertical diaphragm housing position (horizontal position is recommended)

- All parts that come into contact with the product consist of stainless steel or Hastelloy with smooth surfaces.

- The valve is manufactured in an oil and grease-free environment, is self-actuating, and no control line is needed for operation.

- The inert (oxygen-free) atmosphere reduces the risk of fire which could reduce the cost of your insurance premium.

- Tank corrosion is reduced.

- Reduction from very high primary pressure (up to 16 bar) to very low tank design pressures (down to 5 mbar).

- High accuracy settings achieved.