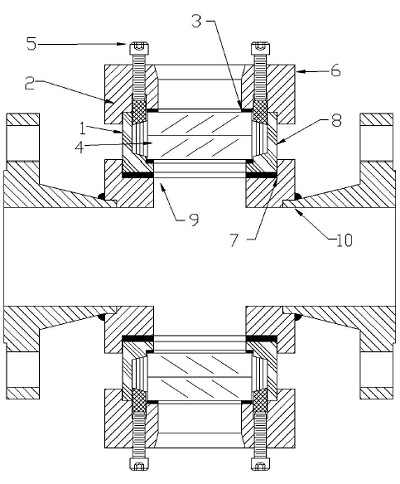

Model I Safesite Sight Flow Indicator

Assembly Instructions

This unit was assembled at the factory and is ready for installation. NOTE: The sight glass should be visually checked for any possible damage during shipping. Alter the unit has been installed; heated and pressurized several times it should be inspected to check for any possible leakage. Ii leakage occurs, follow step (M) until leakage has stopped.

If the lens or packing in the sight glass needs to be replaced alter the unit has been in operation, it is suggested that the packing and gaskets be replaced each time, and the lens be replaced if there are any visual deiects in the glass. When installing parts, reier to steps (A) thru (N).

- (A) Shut down the operating vessel so there is no pressure in the system where the sight glass is operating. Disassemble the unit by removing the cap screws, cap, compression ring, packing, lens, cushion gaskets, insert cup, and mounting gasket.

- (B) The interior of the housing (1O) and the surface for the mounting gasket must be clean.

- (C) Place the insert cup (1) on a flat surlace, serrated face down.

- (D) The interior oi the insert cup (1) must be clean.

- (E) Place the bottom cushion gasket (7) (largest ID) into position.

- (F) Carefully place the lens (4) on the bottom cushion gasket (7).

- (G) Insert the packing (8) between the lens (4) and the interior wall of the insert cup (l) in a normal packing procedure.

- (H) Place the mounting gasket (9) into the flange housing (10). The insert cup (1) can be set in the flange housing (10).

- (I) Place the one piece compression ring (2) on the packing (8) bevelled side down.

- (J) Place the top cushion gasket (3) (smallest ID), on the lens (4) and inside the l.D. of the compression ring (2).

- (K) Take the cap (6) and set it on the insert cup (l). The compression ring (2) must fit into the groove in the cap (6).

- (L) Bolt the cap (6) in place. Bolt pattern NOT SHOWN for mounting sight glass cap (6) to housing (10).

- (M) Insert the compression adjustment screws (5) and tighten incrementally across diameters. This procedure should be followed until all the screws are tight.

- (N) Occasionally, when pressure is applied, the packing (8) will loosen. Should leakage occur, follow the tightening procedure outlined in step (M), until the leakage has stopped.