Model I Weld Sight Glass

Model I Weld Sight Glass

Description:

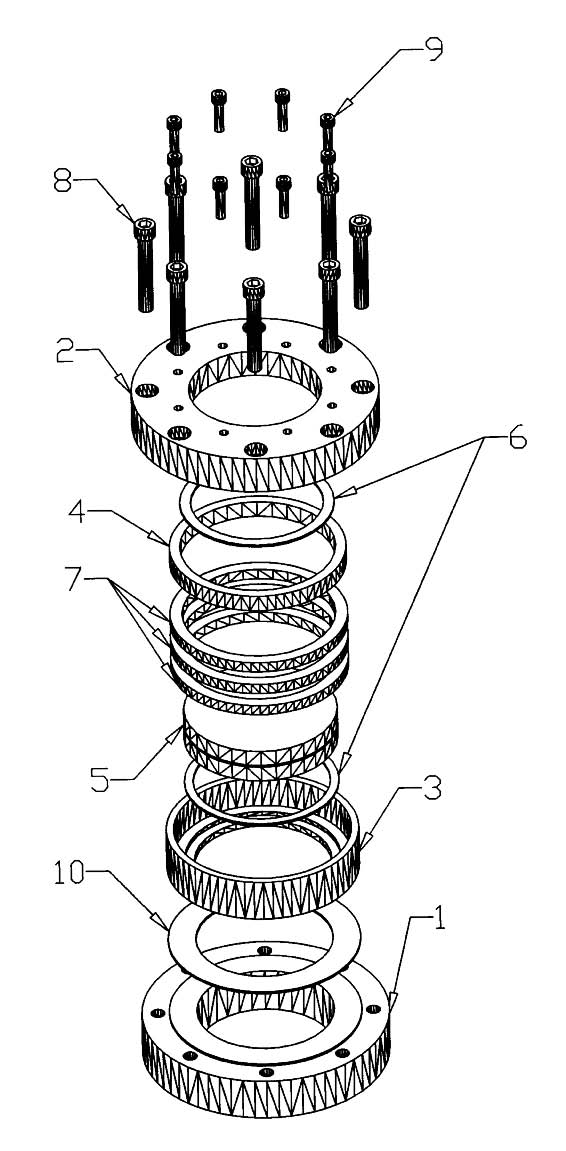

The Model I Weld unit is a combination sight glass and a weld pad. The weld pad is designed to be welded to new or existing equipment to become an integral part of the vessel wall, vessel head, manway cover or in a pipeline system. It is available with the weldment contoured to fit a specific radius (cylindrical or spherical); the sight glass is bolted on the weld pad. The Model I Weld is designed for sizes from 2" to 8."

View Engineering Information >>

Materials of Construction:

- Weld Pad: 316 or 304 Stainless Steel SA-351 or SA-240; Carbon Steel PVQ; Hastelloy; Alloy 20; Titanium; Monel; etc.

- Flange: 316 or 304 Stainless Steel SA-351; Carbon Steel SA-519 or PVQ

- Insert: 316 or 304 Stainless Steel SA-351; Carbon Steel SA-519; Hastelloy; Alloy 20; Titanium; Monel; etc.

- Compression Ring: 304 Stainless Steel SA-351; Carbon Steel SA-519

- Lens: Two-Piece Laminated Tempered Soda Lime (Standard); Tempered or Annealed Borosilicate; Quartz; Lexan; Acrylic; Mica Shields

- Lens Cushion Gaskets: Teflon®; Grafoil®; Gylon®; Blue-Gard®; etc.

- Lens Packing: Combination Teflon® Impregnated and Viton® (Standard); Graphite; FDA Teflon®; etc.

- Retainer Bolts: 18-8 Stainless Steel; Carbon Steel SA-193

- Compression Screws: 18-8 Stainless Steel; Carbon Steel SA-193

- Mating Gasket: Gylon®; Teflon®; Grafoil®; Blue-Gard®; etc.

This sight glass has been certified as maintaining a Quality Assurance System in accordance with the Pressure Equipment Directive 97/23/EC (PED) Annex I, Paragraph 4.3 by the Certification Body 0036 of the TÜV Industrie Service GmbH.