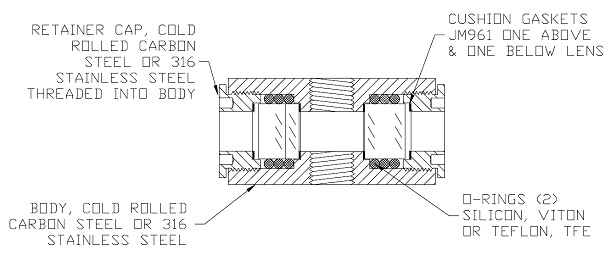

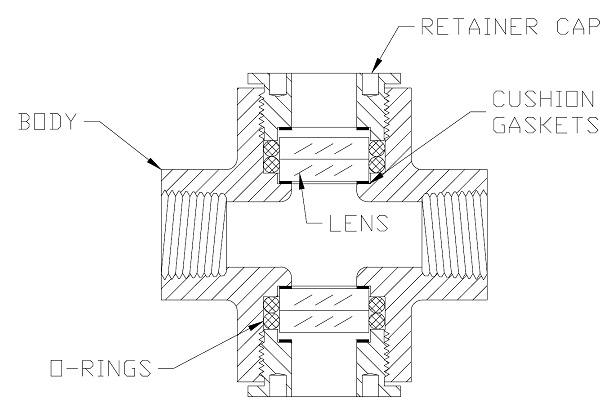

Bull's Eye See-Thru Sight GlassAssembly Instructions  This unit was assembled at the factory and is ready for installation. The sight glass should be visually checked for any possible damage during shipping. To install the unit, thread connecting pipe into the female NPT connection and tighten. Tighten the retainer cap to the body with a spanner wrench. The sight glass is now operational. REMOVAL OF LENS: Unscrew the retainer cap using a spanner wrench or channel-lock pliers. The O-rings are usually removed with a screw type packing remover. If the unit has been in operation, the O-rings will be damaged upon removal and must be replaced to provide a proper seal. The lens usually comes out with the seal, but if not, the sight glass unit should be removed from its service position. Place the sight glass unit upside down on a solid base and lightly hit the unit body to dislodge the lens. The replacement kit contains the necessary gaskets, O-rings and laminated lens to repair a damaged unit. Remove any deposit from bottom seat. Place one gasket on bottom seat. Place lens on gasket. Both O-rings must be forced into the space between the outside of the lens and the inside of the body using a 3/16" dowel rod or similar tool. Place the remaining gasket on top of lens. Thread the cap into the body and tighten with a spanner wrench. This unit is now operational |