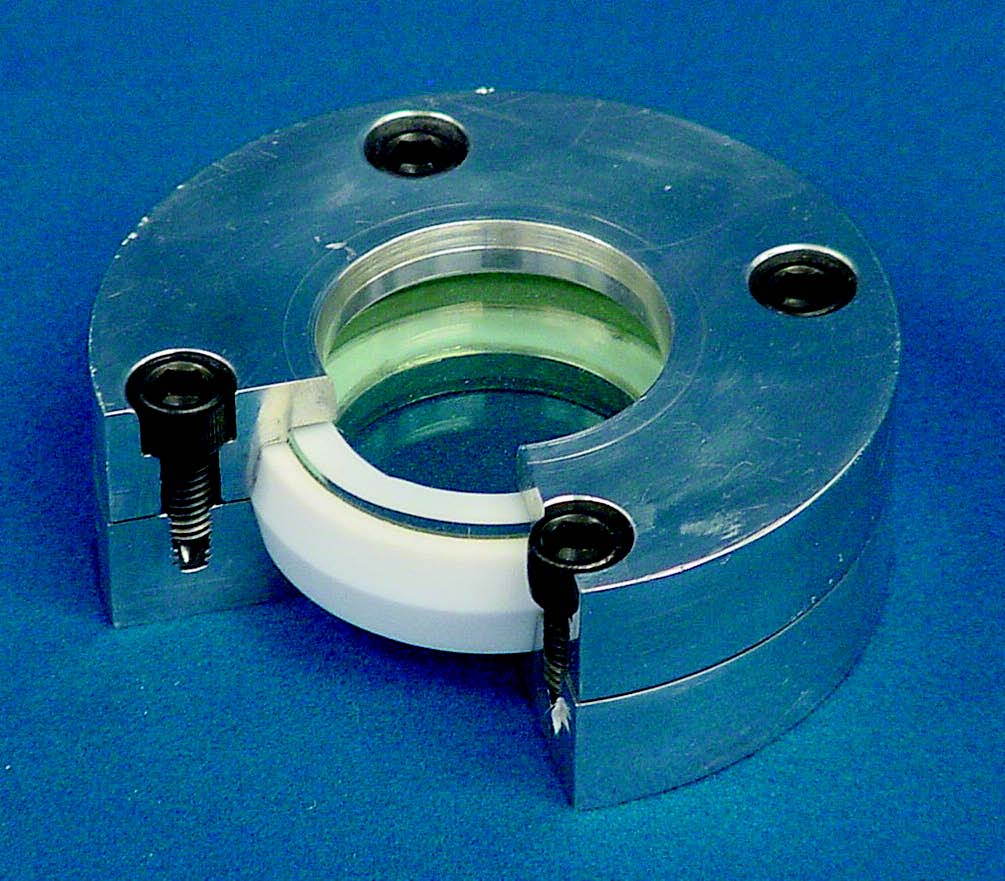

Model L Weld Sight Glass

Description:

The Model L Weld is developed to satisfy the need for pressure requirements from full vacuum to 100 psi while still providing the safety of PresSure Products higherpressure units. This unit is designed to be welded to new or existing equipment, to become an integral part of a vessel wall, vessel head, manway cover or in a pipeline system. It is available with the weldment contoured to fit a specific radius (cylindrical or spherical). The unit is designed for sizes from 2" to 8," and is rated for temperatures up to 450ºF. The Model L Weld can be provided with Silicone, Viton®, Teflon® or EPDM seal, and can be utilized with other types of connections such as buttweld, socket-weld, pipe thread or sanitary. Units can be supplied with built-in spray ring or wiper.

View Engineering Information >>

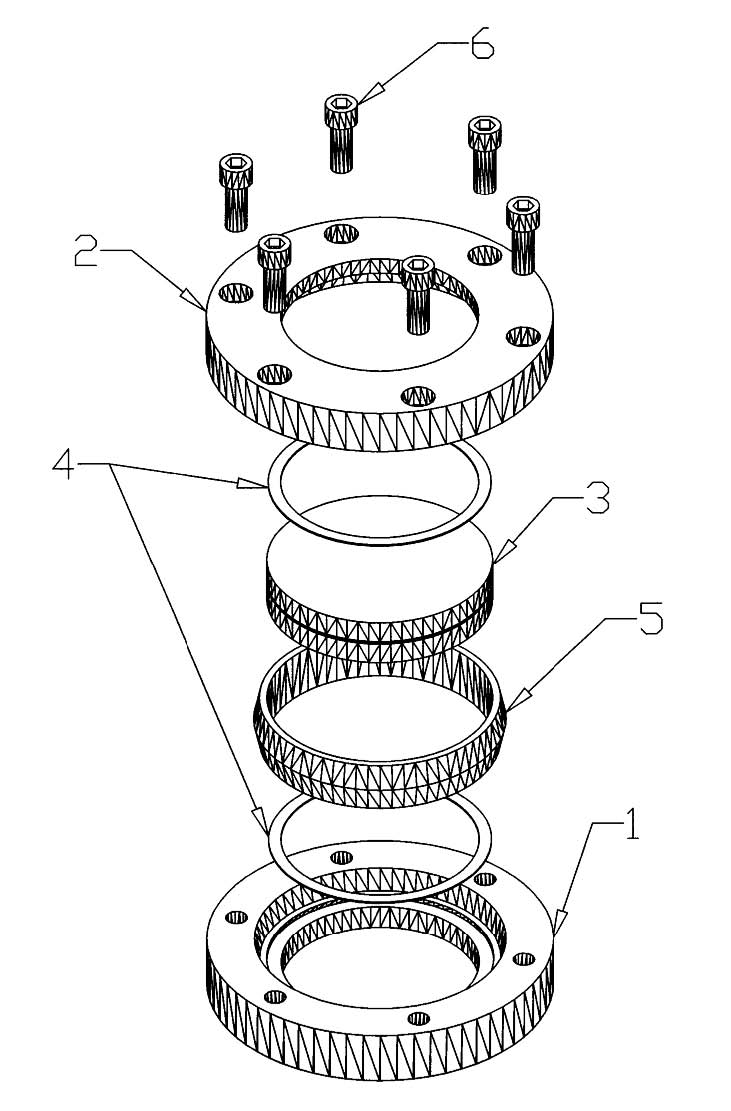

Materials of Construction:

- Body: 316 or 304 Stainless Steel SA-351 or SA-240; Carbon Steel PVQ and SA-516 Grade 70; Hastelloy; Alloy 20; Titanium; Monel; etc.

- Retainer Cap: 316 or 304 Stainless Steel SA-351; Carbon Steel PVQ.

- Lens: Two-Piece Laminated Tempered Soda Lime (standard); Tempered or Annealed Borosilicate; Polycarbonate and Acrylic.

- Lens Cushion Gaskets: Teflon®; Grafoil®; Gylon®; Blue-Gard®; etc.

- Seal: Teflon®; Viton®; Silicone (all standard); EPDM and others (special order).

- Retainer Cap Bolts: 18-8 Stainless Steel; Carbon Steel SA-193.

![]()

This sight glass has been certified as maintaining a Quality Assurance System in accordance with the Pressure Equipment Directive 97/23/EC (PED) Annex I, Paragraph 4.3 by the Certification Body 0036 of the TÜV Industrie Service GmbH.