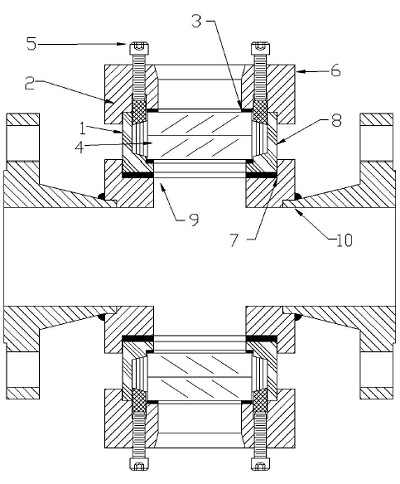

Model I Safesite Sight Flow IndicatorAssembly Instructions This unit was assembled at the factory and is ready for installation. NOTE: The sight glass should be visually checked for any possible damage during shipping. Alter the unit has been installed; heated and pressurized several times it should be inspected to check for any possible leakage. Ii leakage occurs, follow step (M) until leakage has stopped. If the lens or packing in the sight glass needs to be replaced alter the unit has been in operation, it is suggested that the packing and gaskets be replaced each time, and the lens be replaced if there are any visual deiects in the glass. When installing parts, reier to steps (A) thru (N).

|